Profile (inside, outside, or on the design line or vector), pocket, and drill toolpaths are toolpaths where the bit plunges to depth, then stays at that depth for the entire operation or pass.

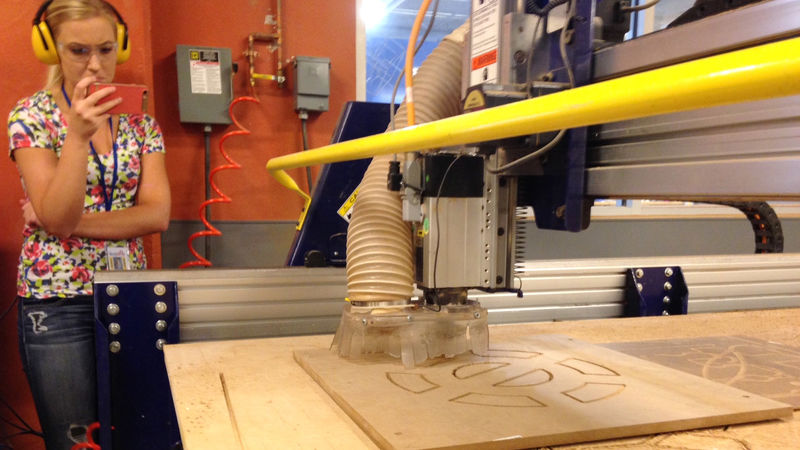

MACHINING TO ONE DEPTH: FLAT END MILL BITS Vacuum and other kinds of hold-down are worthy of a blog of their own, so this blog will concentrate on the types of files that Steve and Dave, faculty members of the theatre program, worked on during training.įor every training, Sallye likes to demonstrate the three major categories of toolpath options, and the bits that are related to those toolpaths. The plumbing for the vacuum hold-down system is not yet in place. As a reminder, the computer station is positioned at the “Front” of the ShopBot (the long rails are the X-axis), and the spindle moves along the gantry in the Y-axis. The ShopBot Control Box is mounted on the far side of the table, away from the operator. The VFD for controlling the spindle is also mounted on the side of the table near where the operator will be. The ShopBot CNC in its final position, with the Becker Pump shut off box mounted on the ShopBot table leg near operator. Steve had a lift jack to move the Becker crate, and a forklift with chains ready to go when the table was partially built and in the approximate final location. The Becker is a heavy critter, and so it helped that Steve and Sallye had planned ahead to know where it would sit under the ShopBot table, and what equipment would help get it out of the crate and into position. The system that they have on their tool uses a Becker Rotary vacuum pump that will pull a vacuum through the top layer of bleeder board (MDF) to hold down a large sheet of material. The first order of business was to get the ShopBot PRSalpha 5’ x 8’ built and the vacuum hold-down system prepared.

#CNC SHOTBOT BUDDY INSTALL#

With the purchase made, Sallye Coyle headed to Ukiah in December, while students were on winter break, to install and train people on the use of the new CNC. The funds for purchasing the equipment came in the form of a Workforce Development grant from the State of California. As part of his hiring contract, he requested a ShopBot CNC router with vacuum hold down and a new welding set-up.

#CNC SHOTBOT BUDDY HOW TO#

But Steve Decker, CVPA Technical Director and instructor of Technical Theatre and Design, had plans for how to update the skills that could be taught through the theatre program at Mendocino College. The back side sports black marker lines for a jigsaw to cut out the leaves and branches, and a metal frame is welded together to provide support. See the specification table for summaries of the work envelope for various Buddy configurations.An old theatre prop in the form of a tree greets you as you enter the back door of the Set Design Studio at Mendocino College in Ukiah, CA. The 14” Z-axis makes the Buddy the perfect tool for mold making, carving, and prototyping. The Buddy 32 and 48 are available with extended-height tablesides and a 14” Z-axis.

The PowerStick is our award-winning motion and drive substrate of the moving table PowerStick technology allows quick swaps between multiple tables and fixturing systems.įor more depth of cutting, Buddys are available with extended-height clearance while 3D cutting. The front-back length can be optionally expanded to 48” with a longer PowerStickTM (actual cutting and machining distances are 26” and 50”, respectively for this axis). The Buddy is available in 32” or 48” widths (actual cutting/machining widths are 32” and 49”) and have a front-back distance of 24”. The gantry is a heavy custom extrusion, precisely machined for sturdy linear rails.The steel and solid aluminum Z-axis also rides on linear rails. They can be configured and reconfigured for specific production needs-Buddys are the agile production CNC solution.įully assembled and ready to work when rolled out of the shipping crate, the Buddy design makes use of a rigid, stationary gantry over a moving table. That makes them useful on the shop floor. Buddys have a small footprint, and can be positioned easily into your production flow. Using advanced technology for CNC cutting, drilling, carving, and machining, ShopBot’s Buddy is easy to learn and use. If you’re looking for a compact CNC solution that delivers affordable, full-production performance in the digital fabrication of wood, plastic, aluminum, and other materials, then ShopBot’s Buddy tool could be the right tool for your needs. The power and precision of full-sized ShopBots

0 kommentar(er)

0 kommentar(er)